Beschreibung

A racing bike with unprecedented aerodynamics!

ALFA, like the first letter of the Greek alphabet α, symbol of „beginning“. The beginning of a new era of hypersonic design and disruptive innovation of current aerodynamic standards.

Since 1961 TITICI has been synonymous with Italian genius and avant-garde spirit. Our philosophy requires us that each new model represents a real innovation, something that did not exist before. From this tradition of innovating comes a new standard of aerodynamics applied to speed,

the ALFA project.

ALFA represents our fastest racing bike ever, born starting from the brand new PAT10 tube, which pushes the boundaries of the possible thanks to a triple approach: unprecedented aerodynamics, exceptional ride quality and design characterized by fluid shapes. This racing bike is equipped with the unprecedented DAC TECHNOLOGY, which offers the maximum advantage in terms of speed, stiffness and comfort.

ONE-PIECE EPS MONOCOQUE FRAME

The carbon monocoque frame of the ALFA is made with the EPS system: the guarantee of the highest construction quality. During production, the carbon sheets are layered around a core of sintered expanded polystyrene (EPS) with a perfectly smooth surface. Unlike the traditional system with inflatable bladders, the EPS system avoids the emergence of air bubbles which cause imperfections and therefore structural weaknesses.

The TITICI technicians have also manaĀed to create a frame in one piece, without joints, a real monocoque! In fact, the frame is extracted from the mold in a single piece, therefore a true monocoque, unlike the majority of other monocoque frames on the market. An amazing and exceptional result, given the complex shapes and the special connection of the seat stays to the PAT tube, already very complicated to achieve with the EPS system, due to its slimmer shape.

The ALFA frame is therefore: more rigid, resistant, and fast. Simply perfect.

NEW PAT10 MONOCOQUE, UCI APPROVED

In the ALFA model, the shape of the PAT tube has been redesigned according to the new UCI frame tube thickness standard. The modification allowed us to obtain the approval of the frame by the international federation, while maintaining its peculiar characteristics of performance, comfort, lightness and functionality.

The top tube flattens out to now a thickness of 10 millimeters, the thinnest in the world. The particular shape allows the TITICI frame to absorb up to 18% of vibrations more than a standard frame without compromising torsional rigidity. The irregularities of the asphalt are thus not transmitted to the arms and back of the cyclist, riding is more comfortable, precise, safe and stable. At the same time, the rigidity guarantees that the power expressed in pedaling is not dispersed, but transformed into outstanding responsiveness and performance.

EXTREME AERODYNAMICS

Extreme shapes, extreme performance. The TITICI engineers, starting from the new studies on the dynamics of penetration of the bicycle in the air, have led to the development of a frame with extreme aerodynamic shapes. In the ALFA model, each single section of the tubes was made following the NACA profile standard to increase the aerodynamic coefficient. Even the blind profiles of the through axle coupling in the fork and the customized housing in the rear thru axle area, designed to hide the electronic group and thru axle cable, have been designed according to a new design that facilitates the passage of the air and avoids negative turbulence.

The result is the fastest and most aerodynamic TITICI has ever produced.

AFT (Aero Flap Technology)

New flat bridge linkined the seat stays to the seat tube. It has a triple function:

1. connect the two seat stays together, avoiding bending of the rear section;

2. combined with the PAT tube, it allows the vertical vibrations coming from the asphalt to be absorbed, increasing driving comfort;

3. participates in the creation of DAC TECHNOLOGY, the double air channels, which optimizes the air flow inside the frame,

allowing the cyclist to save precious seconds in the saddle due to lower friction resistance.

DAC TECHNOLOGY (Double Air Channels)

Brand new technology studied by TITICI engineers, who have created a double air channel on the vertical tube, which is obtained through the advanced front attachment of the high chain stays on the PAT tube and the AFT bridge (Aero Flap Technology).

It serves to channel the air inside the frame for better penetration and lower air resistance. The air flow flows fluidly inside the two channels, positioned on the sides of the vertical tube, with an extremely reduced section and caressing the sharp profiles of the high chain stays, quickly exits the bicycle, allowing the cyclist to save precious seconds in saddle due to lower frictional resistance.

INTEGRATED GEARBOX BATTERY HOUSING

Another detail on which the TITICI engineers focused was on the position of the battery of the electronic gearboxes inside the frame. The goal was to allow the mechanics to intervene quickly on this component, preventing it from negatively affecting the design of the frame, compromising its aerodynamics. The solution was found by creating a slot in the lower part of the seat tube, under the thru axle. The housing is closed with a door secured with two screws, therefore easy to reach and open for normal or extraordinary maintenance.

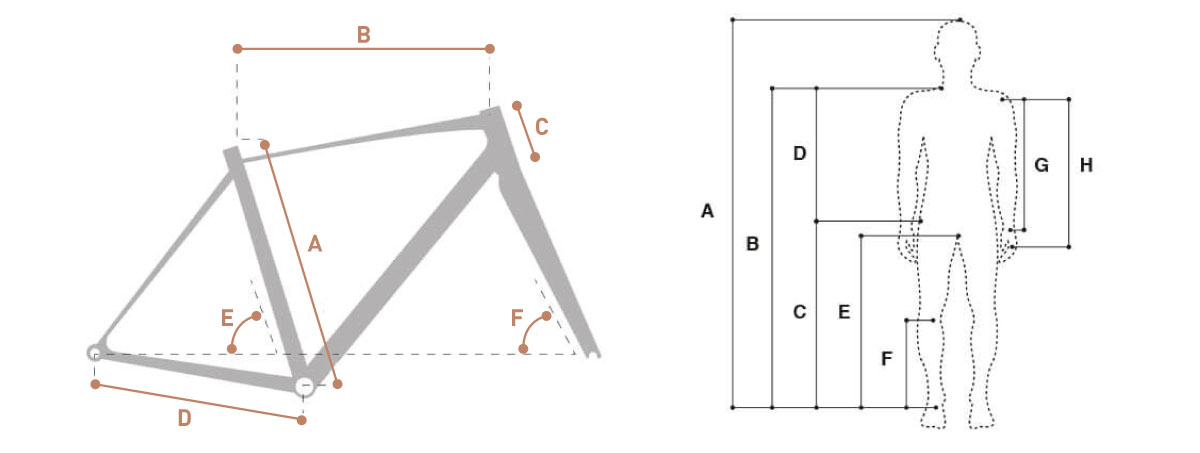

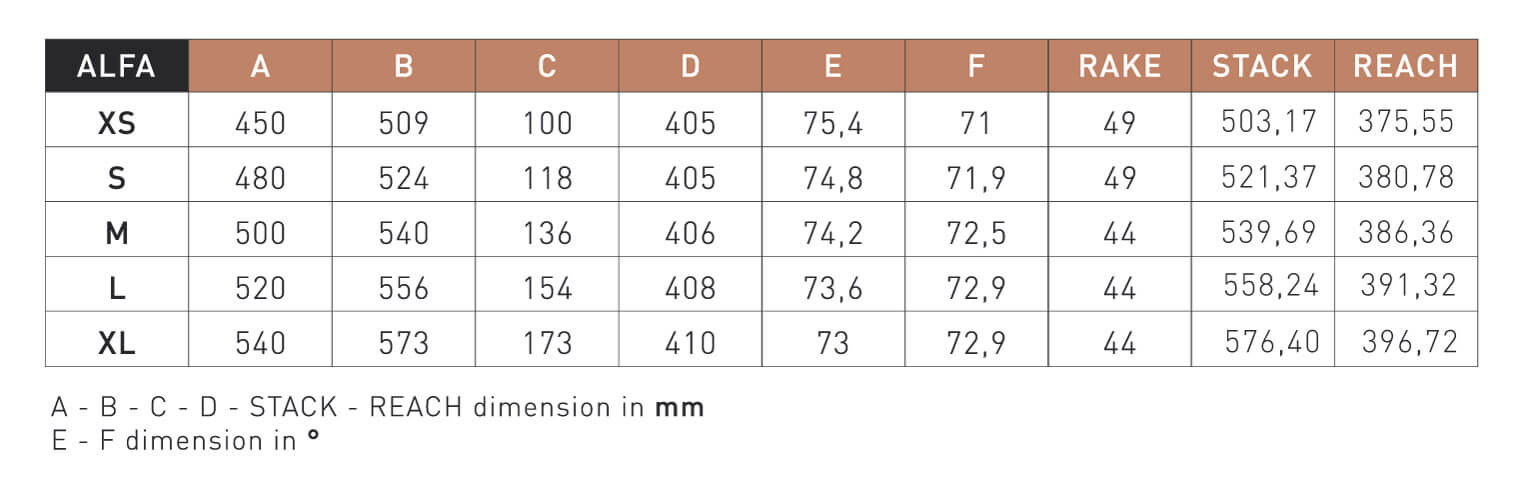

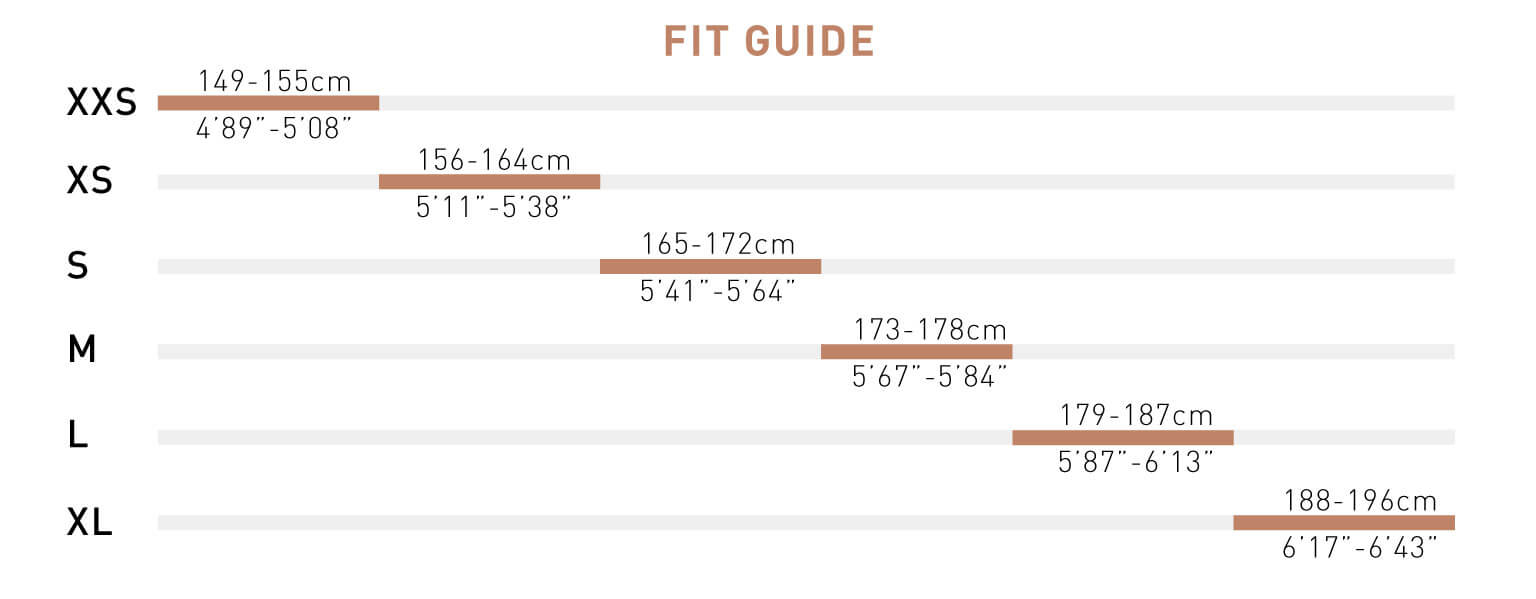

OPTIMIZED GEOMETRIES

The development of the geometries of the ALFA model was carried out using the ‚percentiles‘ method. The percentile method consists in designing the geometry of each single size starting from the human percentiles, or the cyclist’s anthropomorphic data. In this way, the position of the saddle, the length and the inclination of the seat tube are calculated to offer the best and most optimal position for the athlete.

NEW NACA SEAT POST

Every detail has been designed with the aim of obtaining maximum air penetration. The new seat post was therefore designed with a knife shape, with an extremely thin section. Combined with the adjustment integrated in the frame, it is offered in two versions: one with zero offset and one with 25 mm seat back.

FORK LOCKOUT CHECK

To optimize bicycle control and avoid unpleasant accidents during the riding phase, the TITICI technicians have inserted a headset block in the

crown race frame at 40 degrees. A small but important detail, derived from years of experience, sensitivity in the design of frames and from

comparisons with professional athletes.

| TARGET APPLICATION | Aereo Road competition |

| FRAME | Full Carbon Monocoque T.E.C. |

| FORK | New TITICI ALFA DCR |

| ROUTING | Internal |

| SIZES (CM) | XS, S, M, L, XL |

| FRAME WEIGHT | 1110 grams (size M, RTP with hardware) |

| HEADSET | Integrated 1.5″ |

| BB TYPE | Press Fit 386 |

| BRAKE MOUNT | Flat Mount |

| FRONT AXLE | 12×100 mm |

| REAR AXLE | 12×142 mm |

| SEAT POST DIAMETER | Areo Custom ALFA |

| CLAMP | Internal Expander |

| MAXIMUM TIRE SIZE | 700×32 |

| DRIVETRAIN COMPABILITY | Di2, AXS, WRL |

| HANDLEBAR | Vision Metron 5D Evo 3K | |||||

| SEAT POST | Titici ALFA | |||||

| WHEEL SET | Vision Metron 60 SL | |||||

| GROUP SET | Sram Force AXS | |||||

| SHIFTER | Sram Force AXS | |||||

| REAR DERAILLEUR | Sram Force AXS D2 MAX 36T | |||||

| FRONT DERAILLEUR | Sram Force AXS D2 | |||||

| CRANK SET | Sram Force D2 DUB 48/35 | |||||

| CHAIN | Sram Force D1 12S 116L | |||||

| CASSETTE | Sram G 1270 D1 10-36 12V PM | |||||

| DISC BRAKES | Sram Centerline Road 160/140mm C.Lock Sac | |||||

| SADDLE | Prologo Scratch – M5 Tirox | |||||

| TIRES | Vittoria Corsa N.EXT 28-622 G2.0 | |||||

| GRIP | Prologo One Touch – 2 Black | |||||

| WEIGHT (W/O. Pedal) | 7,6 kg |